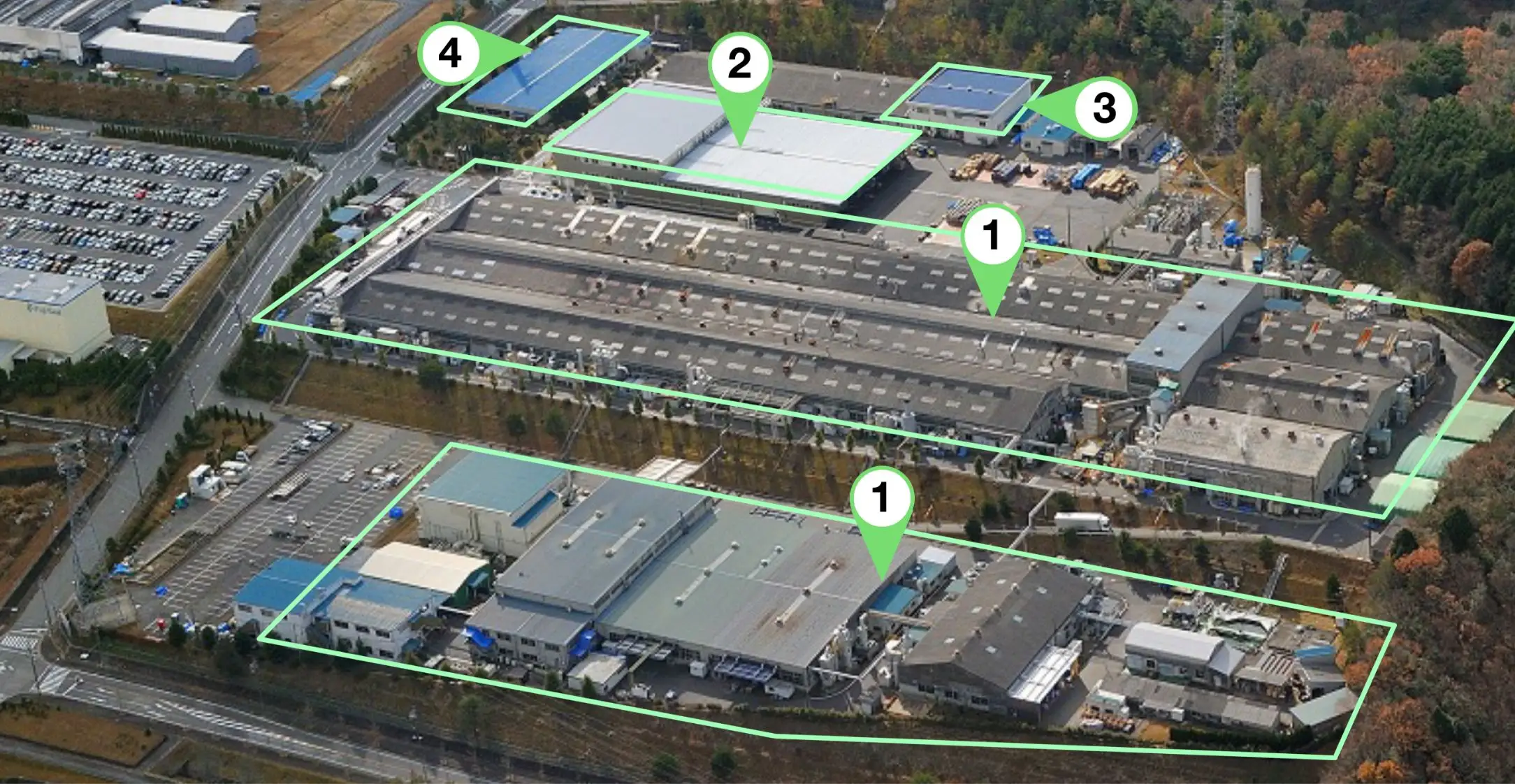

Virtual Factory Tour (Nabari Works)

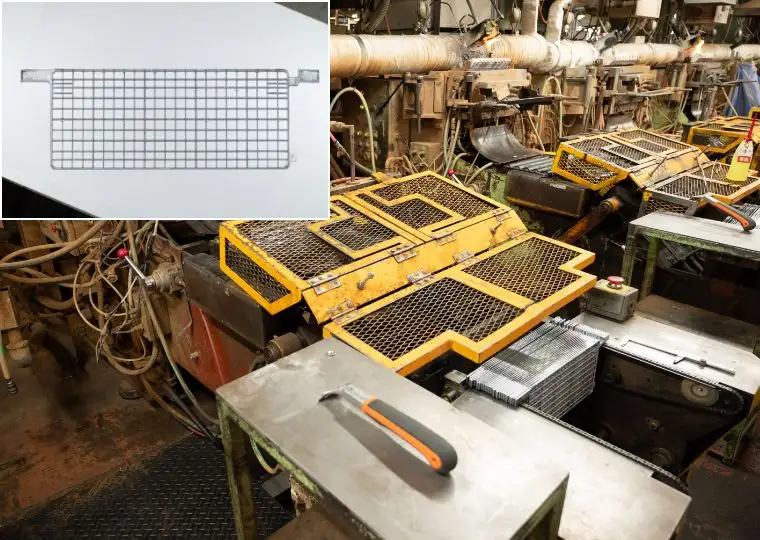

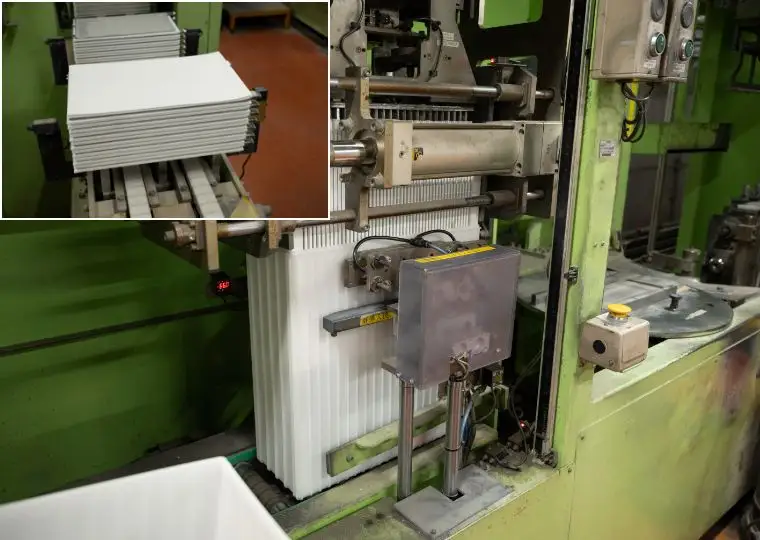

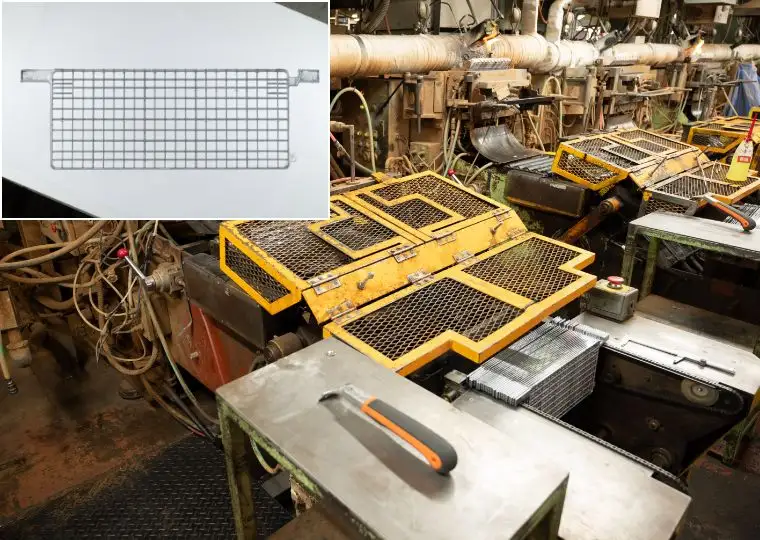

Products Manufactured

Factory Facilities Overview

Battery Production Building

Located within the Yawata Industrial Complex in Nabari City, this building covers approx. 10,000 tsubo (about 33,000 m²) on a site of approx. 30,000 tsubo (about 100,000 m²). It manufactures and ships industrial stationary lead acid batteries, small valve-regulated lead acid batteries, and traction batteries. Environmental facilities such as wastewater treatment systems and dust collectors are also extensively installed.

New Production & Technology Building

This is a combined building that houses both production and administrative functions. The production area handles charging, inspection, and shipment of traction batteries. The office area houses employees from HR & General Affairs, Finance, IT, Procurement, Environmental & Safety Management, Development, Quality Assurance, Production Control, Production Engineering, and Manufacturing Engineering. It is also equipped with a large conference room (capacity 50) and reception rooms.

Technology Building

This building includes inspection rooms used by Quality Assurance, as well as laboratories for Production Engineering and Development. These labs conduct production equipment development, battery testing, prototyping, and technical investigations.

Welfare Building

This building includes an employee cafeteria, locker rooms, and bathing facilities to ensure a comfortable workplace environment. The cafeteria offers a bright and clean space with well-balanced daily menus at reasonable prices.