Visualizing Fleet Operations to Improve Efficiency Forklift Battery Condition Monitoring Service

Identifying How Batteries Are Used — and Proposing Improvements Only a Battery Manufacturer Can Offer

For forklift batteries used daily, proper charging and inspection are essential. If handled incorrectly, they may cause trouble or reach the end of their usable life much earlier than expected.

For example: daily “normal charging,” periodic “equalizing charges,” weekly “electrolyte level checks”…

These routine tasks may be burdensome for busy on-site staff, but such small, consistent actions greatly influence how long and safely a battery can be used.

Supporting these activities is Energywith’s battery monitoring service, “withBMS.”

By monitoring battery conditions 24 hours a day, the system reports whether charging and watering are being performed appropriately, alerts users to early signs of trouble, and visualizes forklift operating conditions through battery-use data. This helps optimize the number of forklifts at each site and improve operational efficiency.

With more than 100 years of battery manufacturing experience, and insights gained through supplying batteries to domestic forklift manufacturers, Energywith provides this monitoring service to help ensure batteries are used safely, properly, and as long as possible.

The service supports all lead-acid batteries for forklifts compliant with JIS standards.

Features of the withBMS Battery Monitoring Service

- 24-Hour Monitoring to Prevent Problems

- Visualizing Operating Conditions to Improve Efficiency

- Regular Reports and Improvement Proposals to Extend Battery Life Safely

24-Hour Monitoring to Prevent Problems

The system detects issues that are difficult to identify externally—such as accelerated degradation caused by insufficient watering or overcharging, abnormal heating, and more.

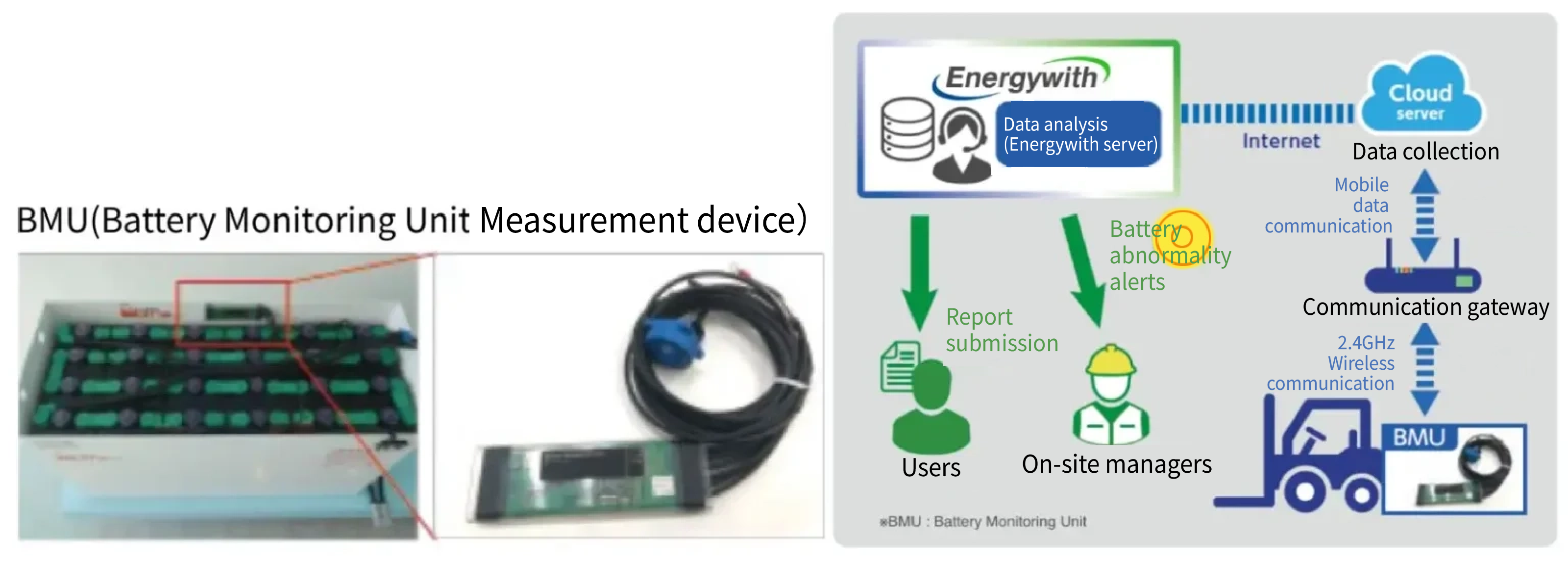

A BMU (Battery Monitoring Unit) is installed on the battery to monitor voltage, current, temperature, and electrolyte level around the clock. Collected data is analyzed by Energywith; if signs of trouble such as abnormal temperature changes or insufficient watering are detected, notifications are sent to users and on-site managers to prevent issues before they occur.

Visualizing Operating Conditions to Improve Efficiency

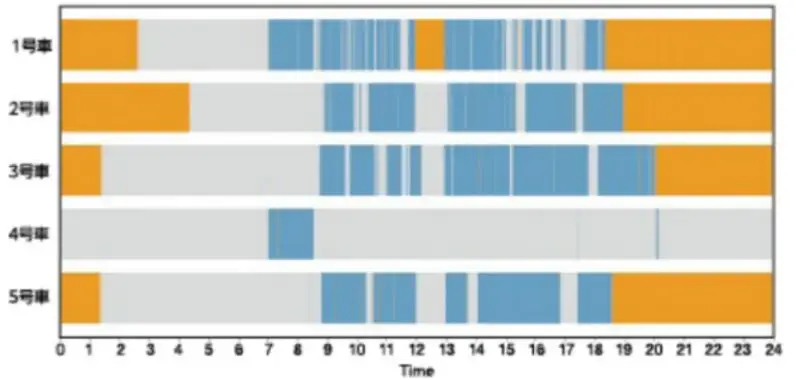

By aggregating data measured 24 hours a day, the system reports actual forklift operating conditions at each site. Because periods of operation, idle time, and charging are clearly visualized, the data can be used to optimize the number and placement of forklifts and operators, improving operational efficiency across locations.

Regular Reports and Improvement Proposals to Extend Battery Life & Ensure Safe Use

Based on collected data, regular reports clearly outline key points regarding watering, charging, and temperature for each battery.

As a battery manufacturer, Energywith proposes improvement measures to ensure batteries are used safely throughout their full expected lifespan.

The system also estimates the appropriate timing for battery replacement based on degradation trends and provides diagnostic notifications grounded in numeric indicators.

Customer Feedback

Company A, Distribution Center (Saitama Pref., Introduced Jan. 2024)

The operation-visualization reports allowed us to optimize the number of batteries and forklift placements.

Company B, Logistics Center (Osaka Pref., Introduced Apr. 2024)

By visualizing actual battery usage, we were able to enforce proper operating methods on-site. Predictive diagnostics also improved the efficiency of inspections.

Company C, Logistics Center (Ibaraki Pref., Introduced Sept. 2024)

We previously needed manual effort to track operating conditions, but after installing withBMS, work efficiency improved.

Monthly reports now serve as a database for categorizing high-use and low-use forklifts/batteries and optimizing operations.

Advice on charging methods also helped prevent battery deterioration.

Company D, Logistics Center (Tochigi Pref., Introduced Nov. 2024)

Monthly reports help us monitor forklift operation and the use of spare batteries. Visualization of on-site conditions makes it possible to verify whether forklift and battery usage is proceeding as expected.