Monitoring System to Prevent Backup Power Battery Failures

Preventing Troubles in Large-Scale and Remote Backup Power Systems

In facilities with a large number of batteries—such as data centers—or in remote infrastructure sites such as base stations, a battery monitoring system can be highly effective.

Energywith uses wireless battery monitoring devices to visualize the status of all lead-acid batteries installed in a customer’s facility. Even at sites where routine inspections are difficult—such as infrastructure facilities that must maintain reliable backup power—the condition of the batteries can be monitored through data.

Do You Face Any of These Challenges?

Energywith’s battery monitoring system addresses such issues leveraging the following three strengths:

- Remote monitoring of battery status without visiting the site, with two-stage abnormality notifications

- Full-cell monitoring reduces maintenance and inspection workload

- Visualization of measurement results helps prevent power failures and facilitates easy data storage

Strengths of Energywith’s Battery Monitoring System

Wireless communication reduces disconnection risks and simplifies installation

Because communication between measurement units (slave units) and the master unit is wireless, the risk of malfunction due to wiring disconnection is low.

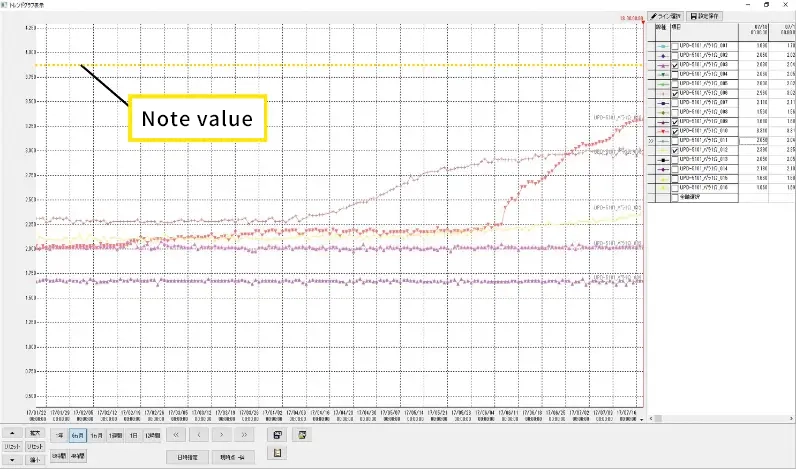

Easy-to-understand graph data and condition diagnostics, with report creation

The system manages measurement data acquired daily—including

① battery voltage,

② internal impedance, and

③ temperature near the battery—

and displays them as trend graphs. Graphing not only clarifies when battery replacement or end-of-life is approaching, but Energywith’s proprietary diagnostic software also makes it easy to understand each battery’s condition through color-coded displays.

In addition, daily and monthly reports can be generated from the stored data.

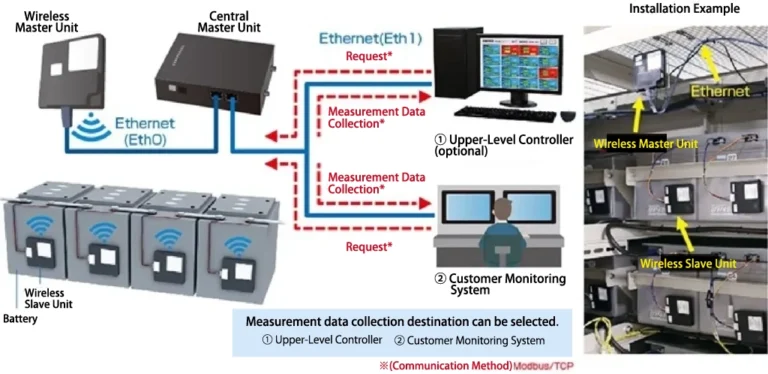

System Overview

Wireless Slave Unit: Installed on each battery

Wireless Master Unit: Installed for each cubicle; collects data from each slave unit

Central Master Unit: Aggregates the data from each master unit and outputs it to the upper-level controller or the customer’s monitoring system

Upper-Level Controller: Aggregates measurement data and displays battery conditions

Related Products