SUPER《LIFTTOP》ECO

This page introduces a lead-acid battery for electric vehicles that plays an active role across a wide range of electric vehicle applications—including electric forklifts—and contributes to a decarbonized society.

Lead-acid batteries for electric vehicles that perform dynamically at material handling and logistics sites incorporate a wide array of advanced technologies. While inheriting these technologies, the product continues to evolve.

With the sealed structure of the negative plates and pressure-cast alloy used for the positive plates, SUPER〈LIFTTOP〉ECO responds to an even wider range of needs.

Features

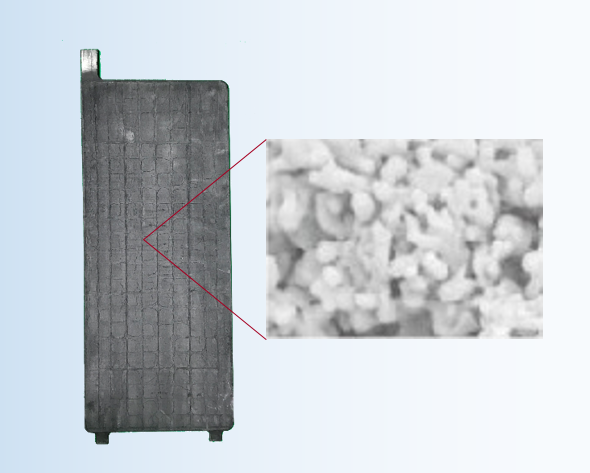

Adoption of Pressure Casting Alloy

By adopting our proprietary lead alloy with a long track record and a pressure casting method, improved corrosion resistance and durability are achieved, along with reduced self-discharge.

- Improved Corrosion Resistance

- Tensile strength is improved by approximately 1.5 times compared with core materials manufactured using non-pressure casting methods.

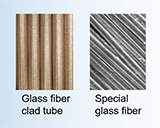

Adoption of Glass Tubes

By adopting glass tubes with excellent heat resistance and chemical resistance, leakage of active material due to deterioration is reduced, achieving long service life.

Positive Plate Active Material

High capacity and long service life are achieved by using our proprietary lead powder.

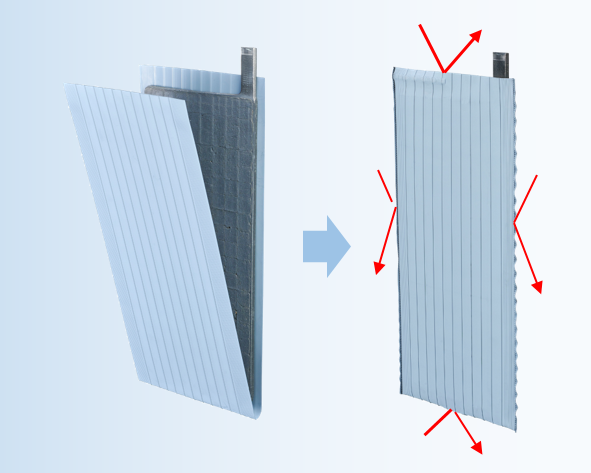

Adoption of Proprietary Separator Wrapping Method

By sealing and wrapping the periphery with separators, internal short circuits from the outside are prevented, contributing to extended service life.

Negative Plates

The reaction surface area is approximately 120% compared with our conventional products, and by adopting our proprietary active material, discharge capacity at low temperatures is improved to 110% of our conventional products.

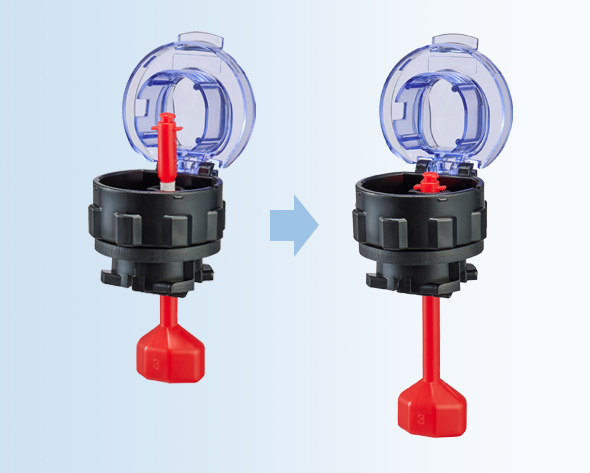

Centralized Water Filling System

Water filling automatically stops when the proper electrolyte level is reached, significantly reducing water filling time.

Electrolyte Level Indicator

Improved visibility through a proprietary design allows the electrolyte level to be monitored by an indicator lamp, preventing electrolyte depletion in advance.

Float-Type Water Plug

The large-diameter design enables easy water filling, while the indicator band for the proper electrolyte level prevents overfilling.

The quarter-turn design allows for easy replacement.

Network

We supply batteries manufactured in Japan and Thailand to dealers worldwide with stable high quality and the shortest possible lead times.

Facilities (Production Plants)

- Japan (Nabari City, Mie Prefecture)

- Thailand

Sales Regions

- Japan

- Asia

- ASEAN

- Europe

- Central and South America