Battery Condition Monitoring Technology for Electric Vehicles

Background to the Development of the Battery Condition Monitoring Service (withBMS)

Lead-acid batteries—highly recyclable and the mainstream choice for electric forklifts—are expected to remain widely used. However, forklifts frequently draw large currents when lifting and transporting heavy loads, resulting in significant load fluctuations. These operating conditions make it difficult to quantitatively assess battery degradation.

Currently, degradation is judged during monthly or annual inspections based on measurements such as electrolyte specific gravity and cell voltage, together with visual checks and years in service. However, performing a discharge test on batteries while they are in operation is not practical. In addition, flooded lead-acid batteries require maintenance such as watering and equalizing charges, and improper maintenance can lead to premature degradation or accidents. To address these issues, we developed a battery condition monitoring service for electric forklifts, enabling 24-hour monitoring and quantitative assessment of battery degradation.

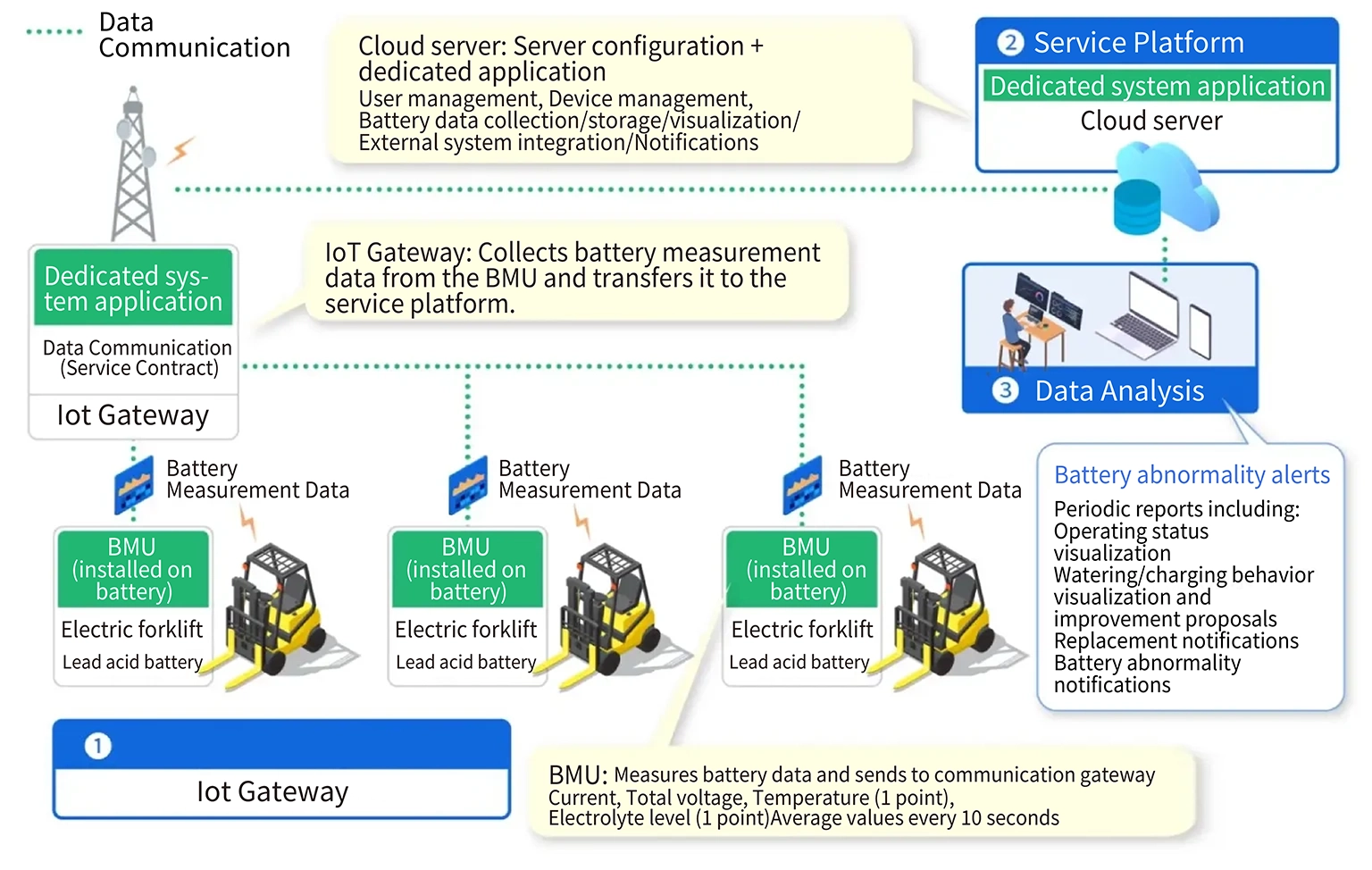

System Overview

The BMU (Battery Monitoring Unit) automatically measures current, total voltage, temperature, and electrolyte level.

The measurement data is then transferred to the service platform via an IoT Gateway (communication gateway).

On the service platform, accumulated battery data is analyzed to generate battery abnormality alerts and periodic reports, which are provided to users as a service.