Next-Generation Nickel–Zinc Battery Technology

Nickel–Zinc Batteries: An Innovative Solution for the Needs of Our Time

We have focused on nickel–zinc (Ni-Zn) batteries, which are safe, environmentally friendly, and recyclable, and have advanced development for automotive and industrial applications.

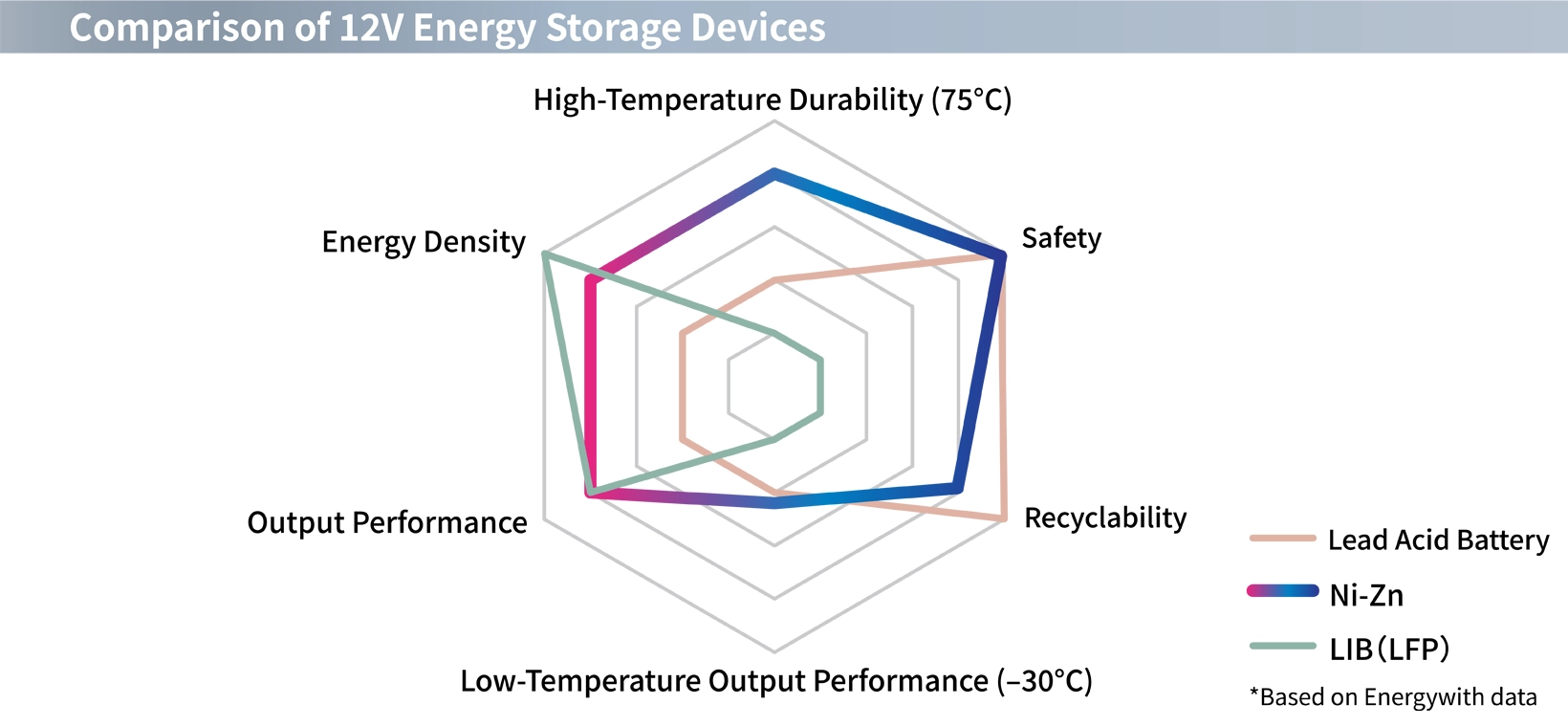

Ni-Zn batteries offer higher energy density than lead-acid batteries and can be made lighter. Although short service life had traditionally been a challenge, we have significantly improved durability through advancements in separators and electrolytes.

As a result, Ni-Zn batteries now deliver performance comparable to lead-acid batteries in starting and auxiliary applications, while achieving approximately four times longer life. They are also well-suited for industrial uses such as electric forklifts and automated guided vehicles (AGVs), where quick charging and repeated cycling are required.

Ni-Zn batteries are expected to be adopted across a wide range of automotive and industrial fields.

Technical Features

High Safety

Because the electrolyte uses water as its solvent, it is non-flammable and safe.

Compliance with Environmental Regulations

Ni-Zn batteries can meet environmental regulations in various countries and are designed with environmental considerations in mind.

Recyclability

They can be recycled after use, contributing to a more sustainable society.

High Energy Density

Ni-Zn batteries offer higher gravimetric energy density than lead-acid batteries and batteries that use the same nickel positive electrode, such as Ni-Cd and Ni-MH batteries. (Ni-Zn: Nickel–Zinc, Ni-Cd: Nickel–Cadmium, Ni-MH: Nickel–Metal Hydride)

Application Areas

Automotive: Engine starting, auxiliary power, backup power

Industrial: Forklifts (electric and engine-powered), material-handling vehicles, AGVs, UPS and other backup power applications

Comparison of 12-V Storage Battery Devices